In today's pursuit of quality of life, tissues are no longer just cleaning tools, but have become a medium for home aesthetics and brand promotion. Many consumers and corporate buyers often struggle with the choice between "embossed" and "printed" tissues. So, what exactly is the difference between embossed and Printed Paper Towel?

1. Different Processing Principles

Embossed Tissue: Embossing is a physical processing technique. Through the pressure of metal rollers, uneven textures (such as diamond patterns or floral patterns) are created on the surface of the tissue. Its main purpose is to increase the thickness of the paper and the adhesion between layers.

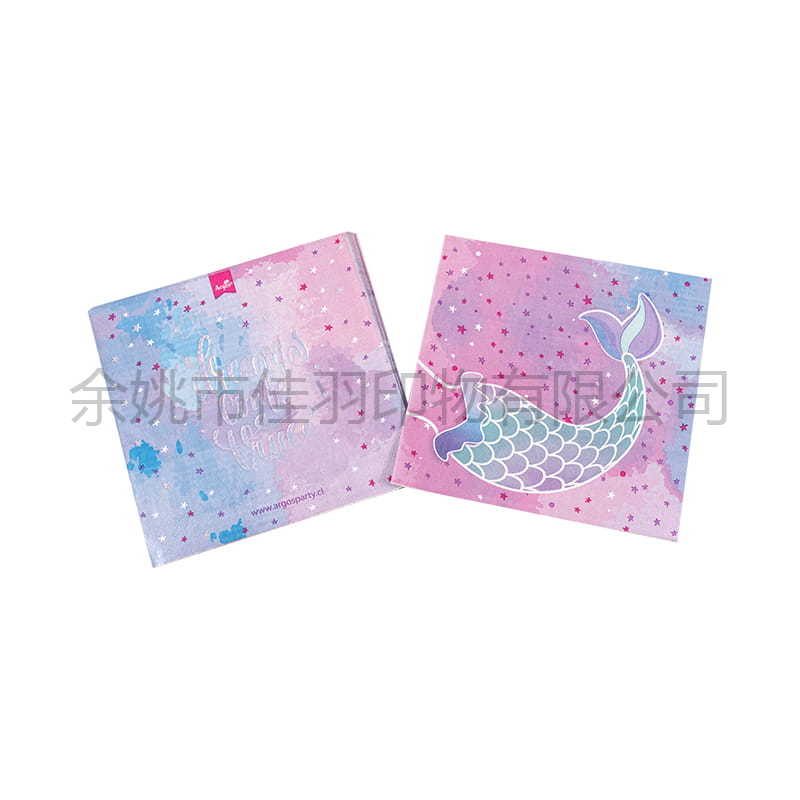

Printed Tissue: Printed Paper Towel, on the other hand, have colors and patterns implanted into the surface of the paper through printing technology. High-quality Printed Paper Towel typically use environmentally friendly water-based inks to present exquisite logos, holiday patterns, or artistic illustrations on the paper. It not only has the three-dimensional effect of embossing (printed products often also have embossing), but also possesses rich visual expressiveness.

2. Visual Effects and Aesthetic Value

In terms of visual marketing, Printed Paper Towel have an overwhelming advantage. Embossed tissues are usually monochromatic, typically pure white, relying on light and shadow to create texture, resulting in a minimalist style. Printed Paper Towel, on the other hand, can achieve vibrant designs, accurately reproducing everything from vintage florals and cartoon IPs to corporate VI colors. This makes Printed Paper Towel the preferred choice for high-end catering, wedding banquets, and branded customized merchandise, greatly enhancing the atmosphere of the usage scenario.

3. User Experience and Functionality

Absorbency: Emboss increases surface area, improving instantaneous water absorption; while high-quality Printed Paper Towel maintain good absorbency while using professional water-based flexographic printing technology, preserving the hydrophilicity of the paper fibers.

Softness to the Touch: Many people worry that printing will harden the paper. In reality, manufacturers use softening treatments during the production of Printed Paper Towel to ensure that the patterned areas remain skin-friendly and soft, without shedding powder or color.

Safety: Compared to ordinary white tissues, the safety of Printed Paper Towel relies more heavily on the quality of the ink. Printed napkins produced by reputable manufacturers all meet food-grade safety standards, ensuring they are non-toxic and odorless, and safe for wiping your mouth.

Why are more and more brands choosing customized printed napkins?

With the rise of the "aesthetics economy," printed napkins have become a mobile form of advertising.

- Brand Communication: Restaurants can significantly enhance customer brand recall by printing QR codes or logos on printed napkins.

- Creating a Sense of Ceremony: At parties or festive celebrations, stylishly designed printed napkins can instantly elevate the ambiance of the table.

- Environmental Trend: Most printed napkins today use virgin wood pulp and biodegradable materials, aligning with the trend of green consumption.

Embossing is practical and simple, while printed napkins represent a perfect combination of practicality and aesthetics. If you want to showcase sophistication in the details, or need to convey your brand philosophy through your product, customized printed napkins are undoubtedly a more cost-effective choice.

English

English 中文简体

中文简体 Español

Español Deutsch

Deutsch